If someone had ever seen an advertisement for Intel, it would have been a sight to advertise Intel engineers wearing dresses from head to toe dancing in the room, looking like astronaut dancing on a spaceship.

And if you have a little technical passion, you are also curious to ask what they are wearing, and if you love it, how do you ever dream of wearing that outfit? Work like them, a fun job? Yes, that is the protective clothing when working in a clean room (such as Intel's semiconductor clean room, for example), and it would not be pleasant to work with. You will ask again, what is clean room? Why clean room? Hope this article will help you with the initial insights on clean rooms.

1. What is clean room?

If you need to simply say, we can say that "clean room" is a very clean room. Cleanroom is, as defined by ISO 14644-1: "A room where the concentration of suspended particles in the air is constrained and it is built and used. The production and retention of particles in the room is reduced to a minimum and other factors in the room such as temperature, humidity, pressure can be controlled and controlled. " Originally in English: "A room in which the concentration of airborne is controlled, and which is constructed in a manner to minimize the introduction, generation and retention of particles inside the room and in which other relevant parameters, eg temperature, humidity , and pressure, are controlled as neccessary. " To put it simply, a clean room is a closed room in which the amount of dust in the air is minimized to prevent contamination of research, manufacturing and manufacturing processes. At the same time, the temperature, pressure and humidity of the air are controlled and controlled to benefit most of the processes. In addition, the room is guaranteed aseptic, no harmful gas in the sense of "clean" of it.

2. History of clean rooms, the need for clean rooms

Clean rooms are used for the first time in the medical field. Preliminary work by Pasteur, Koch, Lister and other pioneering biologists has shown that infections are the cause of many diseases, one of which is the cause of the infection. Hygiene in the environment. For the first time in the 1860s, Joseph Lister (a professor at Glasgow University) set up a closed system to limit dirt and contamination at the Royal Infirmary, is an institute founded by Glasgow University, now known as Glasgow Western Infirmary. This is the first clean room. And the cleanroom system used for production began to be used during the Second World War to improve military guns and weapons. Up until now, the clean room has only been cleaned up by a simple vacuum cleaner and humidifier, which is far from today. Next, the clean room was further developed thanks to the impetus from the nuclear, biochemical, and chemical research fields that led to the introduction of air purification systems. Large clean rooms, better air filtration systems, began to flourish in 1955. Western Electric Company (Winston-Salem, USA) faced problems with the wrong products. Damaged due to the presence of dust particles in the air. Their requirements were clean rooms without dust, and since then clean room systems have been developed, with filtration systems, control systems, protective clothing to prevent dirt. is developed today. And now, clean rooms are used in many fields: medical, scientific and technical materials, electronic components, physical, chemical, biological, precision engineering, pharmaceutical ...

3. Cleanrooms standard

The first standard of clean rooms is the amount of dust, ie the concentration of dust particles suspended in the air is controlled to the extent (of course the dust must be cleaned then). If we compare the human hair diameter to 100 μm, the dust particles in the room may have a diameter of 0.5 to 50 μm (see picture).

.jpg)

Cleanroom standards were first introduced in 1963 in the United States, and are now common standards in the world. These are the standards for determining the amount of dust in a unit of air volume. They are divided into dust sizes and room types determined by the number of dust particles larger than 0.5 μm in volume of 1 cubic foot of air in the room.

a) Federal Standard 209 (1963)

This standard was first defined in 1963 (named 209), and then continuously improved into versions 209 A (1966), 290 B (1973) ..., for to 209 E (1992).

.jpg)

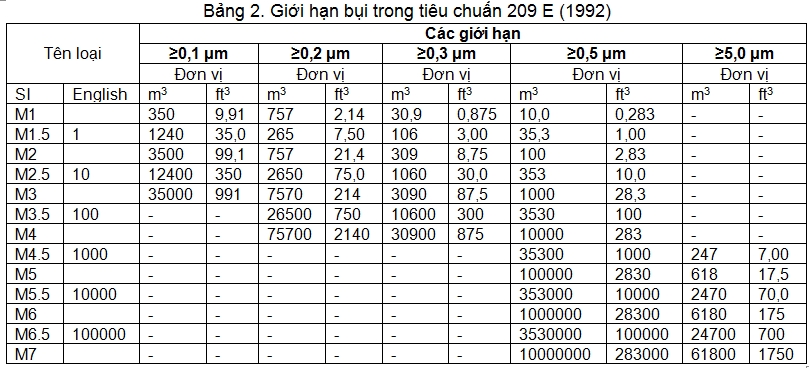

b) Federal Standard 209 E (1992)

This standard determines the amount of dust in the air in standard units (m3). The cleanroom classification is based on the log scale of the dust content of diameters greater than 0.5 μm. Below is the standard table of FS 209 E.

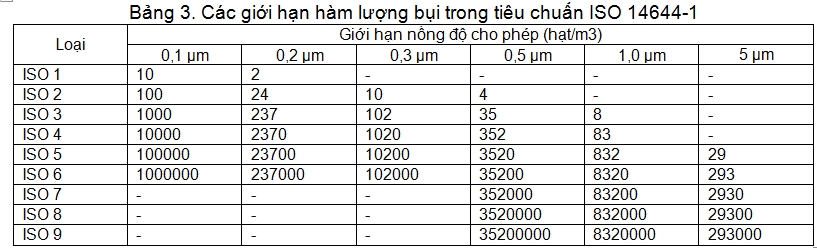

c) ISO 14644-1:

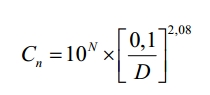

The International Standards Organization (ISO) has set international standards for clean rooms. ISO 14644-1 was issued in 1999, called "Classification of Air Cleanliness". Clean room types are based on the expression:

with:

Cn is the maximum permissible content (in particles / m 3) of the air densities greater than or equal to the size considered.

N is an ISO rating, not exceeding 9, and a minimum allowable index of 0.1

D is the particle diameter in μm

0,1 here is a constant with the dimension μm.

Thus, it is easy to determine the dust limits from the formula and easily classify each clean room level (table 3).

It should be noted that the level of air contamination in the room depends on the dust particles produced in the room, not just the fixed number of rooms. Therefore, in the standards of the room, always require continuous cleaning systems and also regulations on the room size and number of people, the number of possible activities in the clean room. In addition to these standards, each sector may also have its own requirements, for example, in the field of semiconductor industry that requires different industry. ... I remember that the semiconductor industry manipulated material particles up to microns, hence strict requirements for small dust content, while the health sector requires high levels of cleanliness and air conditioning to prevent contamination.

Source: Ngo Duc The, G12 8QQ, UK

- How to Choose the Right Partition for a GMP Cleanroom (10.02.2025)

- Cleanroom Design Styles (04.03.2018)

- Equipment needed for cleanrooms (03.04.2018)

- HEPA Filter (10.04.2018)

- What's Airlock? (28.03.2019)

- What is Clean Bench? (08.05.2019)

- Differences between Latex gloves, Nitrile gloves and Vinyl gloves (27.08.2019)

- List of antistatic gloves used in clean rooms (21.08.2019)

- Classification of air filters and periodic replacement times (29.02.2024)

- Cleanbooth (26.12.2023)