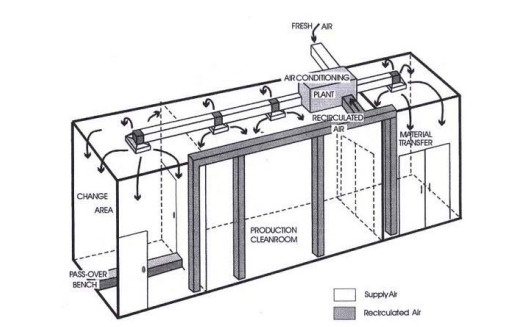

1. Turbulently Ventilated Cleanroom:

The principle of ventilation of this type of clean room is similar to most common air conditioning room such as office or shop. The air (clean) supplied by the air conditioner is radiated through the diffuser on the ceiling (picture).

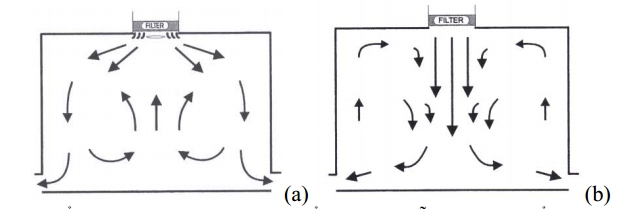

This is called "chaotic ventilation" due to the absence of random and chaotic movement in the room due to the diffusion system (Picture 2a) or the "spray" system (Picture 2b).

The air-spraying system (Picture 2b) is commonly encountered in conventional chaotic ventilated systems. This type of system usually provides direct airflows and is well suited for controlling contamination under the filter. This spray system can provide the more favorable conditions below the supply area, but thus lessens the surrounding areas in the room (Picture 3).

2.Unidirectional Cleanroom

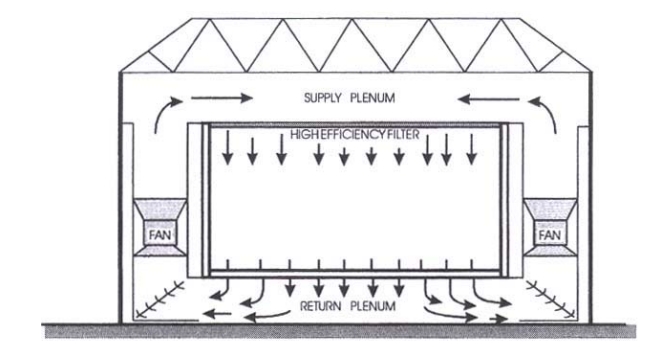

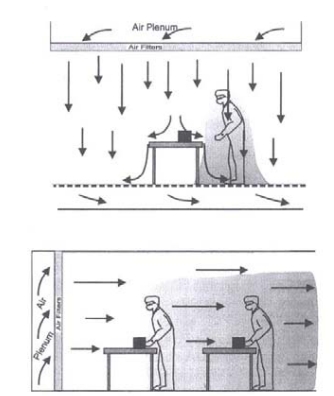

Cleanroom systems with diffuse ventilators usually achieve only standard deviations of up to ISO 6 levels during production. In order to achieve better conditions during operation, it is necessary to dilute the production of the particles. This can be achieved by using a completely straight air flow (Picture 4).

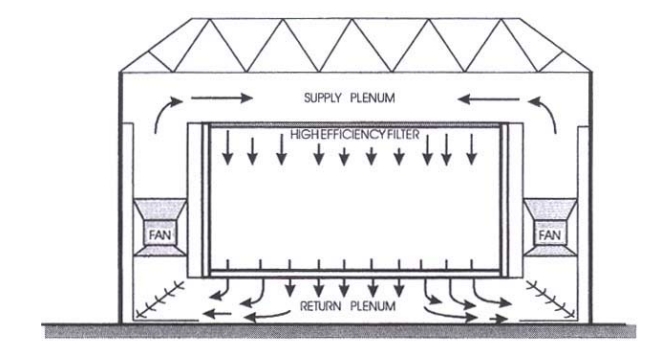

Figure 4 is a cross sectional view of a clean room design with vertical air flow and closed-loop operation in the same manner as the pistons. Therefore, this air stream helps to propel the contaminants. When discharged to the door, this air stream is transported in line and re-circulated through the filtration system. This system is much more advanced than the turbulent exhaust system because of its rapid removal of contaminants. The velocity of gas flow is usually between 0.3 m / s and 0.6 m / s. However, this type of clean room is more expensive and operating costs are much higher than the cleanroom turbulence.

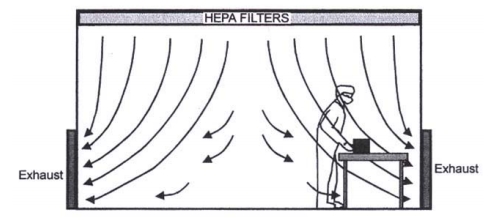

Another type of orientation cleanroom system is the horizontal airflow system (Picture 6), with the way that air enters from this side wall through a high efficiency filtration system and blows through the room, after banging on the opposite wall. Because the area of the wall is often much smaller than the ceiling area, the cost of this room is also lower than that of the vertical air flow.

The horizontal air circulation system is not widespread by vertical systems, although it is cheaper for reasons related to contamination (see Picture 7). Figure 8 compares two ways of diluting contamination in two types of horizontal and vertical rooms. In rooms with vertical discharge, dirt will be pushed vertically to the floor, and the canvas can be vented to the exhaust positions and not contaminate from one location to another and from one person to another. others. Horizontal airflow can lead to dirt being blown from one location to another, or from the front (flowing air) to the rear (Picture 7).

Clean room systems with vertical airflow are widely used in the semiconductor industry and material technology (Picture 8) in recent years. In semiconductor technology and material technology, the air is filtered with very high purity and is blown from the ceiling.

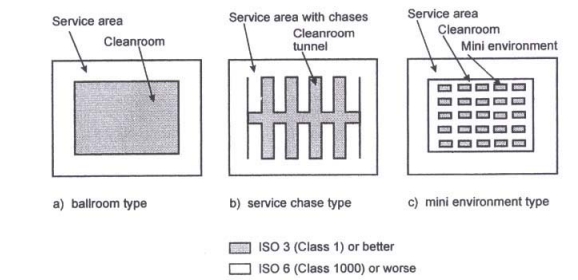

Rooms can be arranged in different styles to form clean rooms. The type shown in Picture 8 is called "ballroom" because we will have a clean room (full space as a room in the ball). This type of room has a ceiling that is a high-performance gas filter that provides gas for the entire workshop no matter where the machine is located. In fact, the best quality of air is only needed where the product rotates in the direction of dust contamination and in other areas can accept less quality air. With this in mind, one can make clean rooms less expensive and another type is the small room in an axle - this is called the service chase (Picture 9b). Each child room will have a high standard of cleanliness, while the outer areas may have lower cleanliness. The sub-rooms are located along a tunnel (this is the clean room I'm working on). This type of clean room costs less to operate than the ballroom.

Ballroom rooms can also be divided into small function rooms (Picture 9c) and, of course, in each of the small rooms will be extremely clean and the service area will have a lower purity.

* Air filter system for clean room

The air in the clean room must meet the dust level requirements so there is always a need for dust filters. Since 1980, a widely used filter system has been called High Efficiency Particle Air (HEPA). HEPA is a system that filters dust into the air at 99.97% efficiency for dust up to 0.3 μm. Today, HEPA is also equipped with bacterial filtration and inert particles.

%20v%C3%A0%20c%C3%A1c%20n%E1%BA%BFp%20g%E1%BA%A5p%20nh%E1%BB%8F%20(b).jpg)

The air is filtered through rolls of filter paper rolled into layers of media ranging in width from 15 to 30 cm and separated by thin aluminum foil. In order to prevent particulate matter, the filter media is used as microwaves arranged in microscopic nets (Picture. 11a) and thus allow the air to pass through, simultaneously blocking the dust particles.

%20v%C3%A0%20c%C6%A1%20ch%E1%BA%BF%20l%E1%BB%8Dc%20b%E1%BB%A5i%20c%E1%BB%A7a%20t%E1%BA%A5m%20l%E1%BB%8Dc%20(b)%20v%C3%A0%20hi%E1%BB%87u%20su%E1%BA%A5t%20l%E1%BB%8Dc%20(c)_%20.jpg)

- How to Choose the Right Partition for a GMP Cleanroom (10.02.2025)

- What is a Cleanroom? (04.03.2018)

- Equipment needed for cleanrooms (03.04.2018)

- HEPA Filter (10.04.2018)

- What's Airlock? (28.03.2019)

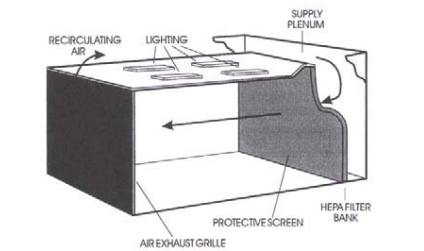

- What is Clean Bench? (08.05.2019)

- Differences between Latex gloves, Nitrile gloves and Vinyl gloves (27.08.2019)

- List of antistatic gloves used in clean rooms (21.08.2019)

- Classification of air filters and periodic replacement times (29.02.2024)

- Cleanbooth (26.12.2023)